New Guide to Selecting and Machining Plastics Details Easy-to-Machine Materials

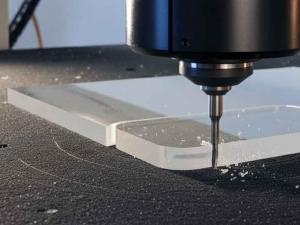

Interstate Advanced Materials released a new guide that compares easy-to-machine plastics, offers CNC starting points, and helps with machining plastic parts.

The jump from metal to plastic machining can be frustrating without the right tools. This guide helps shops pick the right plastic, dial in their programs faster, and cut plastic parts more reliably.”

SACRAMENTO, CA, UNITED STATES, November 13, 2025 /EINPresswire.com/ -- Interstate Advanced Materials has released Machinable Plastics: A Machinist’s Guide, a new technical resource on the Interstate Plastics website that helps CNC machinists, machine shops, and fabricators answer two critical questions: which plastics are easiest to machine for a given job, and how to machine them for consistent results.— Christopher Isar

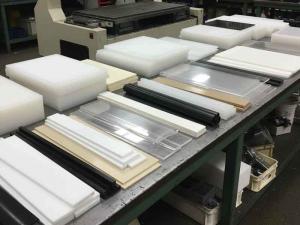

The guide organizes common shop plastics by relative cost, ease of machining, and typical applications, then calls out the shop-floor issues that often lead to scrap. It covers acetal, HDPE, ABS, rigid PVC, acrylic, polycarbonate, nylon, polypropylene, KYDEX/Boltaron, UHMW, and PTFE, along with specialty and high-performance materials like PEEK, Ultem (PEI), Torlon (PAI), Vespel (PI), PPS, PVDF, PPSU, PET, Noryl, PETG, and more. Each material includes notes on when to choose it, what to watch for in the cut, and where it’s commonly used.

For machinists coming from metalworking, the guide highlights the key differences that change setups and programs: plastics hold heat instead of wicking it away, many grades creep under clamping force, and tool geometry must focus on sharp, high-rake edges that shear rather than rub. The guide walks through chip evacuation, coolant compatibility, and the rough-then-finish strategies needed to hold tolerances without warping parts.

The new guide provides practical starting points for CNC routers and mills, including example RPM, chip load, feed rate, depth of cut, and width of cut for each material. It also documents real-world problems, such as chip welding in ABS, delayed stress cracking in polycarbonate, moisture-driven movement in nylon, chatter in thin HDPE, melting in UHMW, and creep in PTFE, and gives specific corrective actions for each.

The guide is designed to help machinists:

-Quickly compare common machinable plastics by ease of machining, cost, and typical use cases

-Choose between clear plastics like acrylic and polycarbonate based on edge quality versus impact resistance

-Select materials for wear strips, low-friction components, chemically aggressive environments, or food and medical applications

-Adjust toolpaths and workholding to reduce heat, deflection, fuzz, and burrs on flexible or low-melt materials

-Establish realistic tolerances and finishing strategies for different plastics, from acetal to UHMW and PTFE

Beyond material selection, the guide includes a plastic machining pre-flight checklist, safety and PPE recommendations, and a machinable plastics FAQ and decision guide that addresses common shop questions such as how to keep nylon parts in tolerance, when to anneal polycarbonate, how to drill and tap plastics, and what to expect for minimum wall thickness and feature size.

The new machinist’s guide is available now on the Interstate Plastics website as part of Interstate Advanced Materials’ expanded technical resource library for fabricators, machinists, and engineers. View it now at https://www.interstateplastics.com/machinable-plastics

Interstate Advanced Materials is a full-line distributor of high-performance sheet, rod, tube, plate, and bar, and proudly serves many diverse industries, including OEM, semiconductor, food processing, POP display, government, agriculture, automotive, and many others. With 10 locations nationwide and an online sales and support team, Interstate Advanced Materials provides full sheets and pallets, cut-to-size service, complex CNC, welding solutions, and full machining capabilities.

Interstate Advanced Materials is known for selling high-quality products, providing excellent customer service, and providing superior technical support. Excellence in all facets of the customer experience has been the cornerstone of Interstate Advanced Materials for over 45 years.

Christopher Isar

Interstate Advanced Materials

4154041900 ext.

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.